Auburn Hills, MI, October 4, 2011 – Esys, a leading innovator of full service automation and software solutions for manufacturers announced today it had completed commissioning of the Anti-chip and Cosmetic Seam Seal flex production cells at a major OEM Assembly Plant. For this engagement, Esys pioneered an innovative machine that achieves dramatic improvements in precision of anti-chip/rocker panel spray coatings. The AutoMaskTM rotary masking tool for robotic coating applications is easy to maintain

and reliably delivers a perfect spray line without on-vehicle masking. In the highly automated world of vehicle assembly, precision and quality are critically intertwined attributes, and AutoMask delivers on both counts.

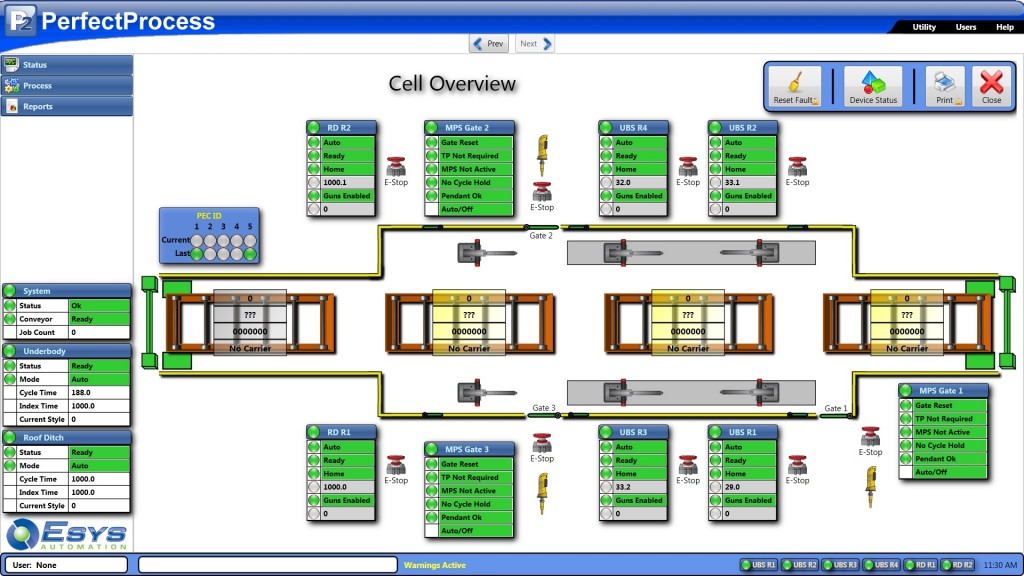

Automask is the latest addition to Esys Automation’s open architecture for paint and dispense solutions. Open architectures provide OEM’s choice, flexibility, and maintainability by allowing customers to independently select the best robotics, vision systems, controls, and equipment available today. Esys PerfectProcessTM software completes the solution footprint, delivering powerful, exacting control over the many variables that impact a coating process, such as surface contours, temperatures, pressure, and material viscosity.

The company was selected as the turn-key general contractor for the showcase OEM project in 2010. Esys provided comprehensive architectural and engineering responsibilities from design and simulation, to solution commissioning for this high-profile product launch. Esys engineers coordinated every phase of the project, including materials handling and conveyance, robotics, controls, structural integration of support systems, and integration with existing line production operations.

“I’m very proud of our team’s performance, and of the confidence our customer placed in us for such a ground breaking product launch.” said David Valentine, President of Esys Automation. “This is just one more example of how technology can help revitalize our country’s manufacturing footprint, helping us better compete in the global automotive manufacturing business.”

Esys Automation Paint and Dispense applications are employed in a variety of OEM final assembly lines today, including anti-chip/rocker panel coatings, roof ditch applications, underbody and interior seam sealing, and liquid apply sound dampening. In addition to paint and dispense applications Esys Automation is a global market leader in tire and wheel assembly solutions, and recently introduced AutoW8t, revolutionizing wheel weight apply in high-volume production environments.

For information about Esys, Inc and its products and services, visit www.esyscorp.com, e-mail info@esyscorp.com, or call 1.248.754.1900, extension 260.

About , Inc.

![]()

Esys specializes in innovative manufacturing automation solutions designed to meet exacting tolerances, enhance operational efficiency, and improve visibility, tracking, and control of production processes. Headquartered in Auburn Hills, Michigan, Esys operates across North America, including Canada and Mexico.

For more information, please visit www.esyscorp.com.